Maximizing Efficiency: Advanced Gas Generation and Air Drying Systems

In today’s rapidly evolving industrial landscape, maximizing efficiency is paramount for businesses seeking to stay competitive and sustainable. One area where significant gains can be made is in gas generation and air drying systems. In this comprehensive guide, we explore the benefits, applications, and advancements of advanced gas generation and air drying technologies, including N2 generator and compressed air dryers.

Introduction to Gas Generation and Air Drying Systems

Gas generation and air drying systems play a crucial role in various industries, providing essential gasses and ensuring the quality and reliability of compressed air. Traditional methods of gas supply, such as cylinder delivery or liquid storage, can be costly, inefficient, and prone to supply chain disruptions. Advanced gas generation systems, such as N2 generators, offer a more reliable and cost-effective solution, producing nitrogen on-site as needed. Similarly, compressed air dryer removes moisture from compressed air, preventing corrosion, contamination, and operational issues.

Benefits of Advanced Gas Generation Systems

Advanced gas generation systems, such as the N2 generator, offer numerous advantages over traditional gas supply methods. By producing nitrogen on-site from compressed air, these systems eliminate the need for costly cylinder delivery or liquid nitrogen storage, reducing expenses and logistical headaches. Additionally, N2 generators provide a continuous and reliable nitrogen supply, ensuring uninterrupted operations and improved efficiency.

Applications of N2 Generators

N2 generators find applications across various industries, including industrial manufacturing, food packaging, electronics, and pharmaceuticals. In industrial manufacturing, nitrogen is used for blanketing, purging, and inerting applications to prevent oxidation, combustion, and contamination. In the food industry, nitrogen is employed for packaging and preservation to extend shelf life and maintain product freshness.

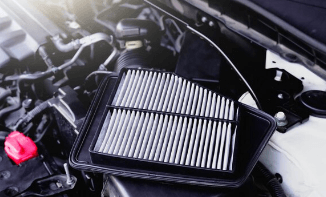

Advantages of Compressed Air Dryers

Compressed air dryers play a critical role in ensuring the quality and reliability of compressed air systems. By removing moisture from compressed air, these systems prevent corrosion, contamination, and operational issues caused by water vapor. Additionally, compressed air dryer help extend the lifespan of equipment and reduce maintenance costs associated with moisture-related issues.

Integration of Gas Generation and Air Drying Systems

The integration of N2 generators and compressed air dryers offers synergistic benefits for businesses looking to maximize efficiency and streamline operations. By combining these systems, businesses can ensure a continuous and reliable supply of both nitrogen gas and dry compressed air, reducing reliance on external suppliers and minimizing downtime.

Technological Innovations in Gas Generation Systems

Recent advancements in gas generation technology have led to the development of more efficient and versatile systems. On-site generation capabilities allow businesses to produce nitrogen gas directly at the point of use, eliminating the need for storage and transportation of gas cylinders. Additionally, advanced monitoring and control features enable businesses to optimize system performance and minimize energy consumption.

Environmental Impact and Sustainability

In addition to cost savings and operational benefits, advanced gas generation and air drying systems offer environmental advantages. By producing nitrogen on-site and eliminating the need for transportation and storage, N2 generators reduce carbon emissions and reliance on fossil fuels. Similarly, compressed air dryers help conserve energy and resources by preventing the waste of compressed air and reducing the need for equipment maintenance and replacement.

Cost Considerations and Return on Investment

While the initial investment in advanced gas generation and air drying systems may seem significant, the long-term savings and return on investment are substantial. By eliminating the ongoing costs of gas cylinder delivery and reducing energy consumption and maintenance costs associated with moisture-related issues, businesses can achieve significant cost savings over time.

Choosing the Right System for Your Needs

When selecting a gas generation or air drying system, it’s essential to assess your production requirements, capacity, and budget constraints. Consulting with experts in the field can help businesses identify the most suitable solution for their specific needs and objectives, ensuring optimal performance and cost-effectiveness.

Maintenance and Service

Regular maintenance is crucial for ensuring the continued reliability and efficiency of gas generation and air drying systems. Access to reliable technical support and spare parts is essential for addressing any issues that may arise and minimizing downtime. By investing in preventive maintenance and partnering with reputable service providers, businesses can maximize the lifespan and performance of their systems.

Case Studies: Successful Implementations

Numerous industries have benefited from the implementation of advanced gas generation and air drying systems. Case studies showcasing successful implementations highlight the transformative impact of these technologies on businesses’ efficiency, productivity, and bottom line.

Future Trends and Developments

Looking ahead, the future of gas generation and air drying systems is promising, with continued advancements in technology driving innovation and market growth. As industries increasingly prioritize efficiency, sustainability, and cost-effectiveness, demand for advanced gas generation and air drying solutions is expected to grow, leading to further expansion of applications and adoption across various sectors.

Conclusion

In conclusion, advanced gas generation and air drying systems offer a compelling solution for businesses seeking to maximize efficiency, productivity, and sustainability. By producing nitrogen on-site and removing moisture from compressed air, these systems provide a reliable and cost-effective source of essential gasses while reducing environmental impact and operational costs. With technological advancements driving innovation and market growth, the future looks bright for businesses embracing advanced gas generation and air drying technologies.

FAQs (Frequently Asked Questions)

What is an N2 generator, and how does it work?

An N2 generator is a device that produces nitrogen gas on-site from compressed air. It works by separating nitrogen molecules from the surrounding air using various techniques, such as membrane filtration or pressure swing adsorption.

What are the benefits of using an N2 generator compared to traditional nitrogen supply methods?

N2 generators offer numerous advantages, including cost savings, reliability, and convenience. By producing nitrogen on-site, businesses can eliminate the need for cylinder delivery or liquid nitrogen storage, reducing expenses and logistical headaches.

How can compressed air dryers help improve equipment performance?

Compressed air dryers remove moisture from compressed air, preventing corrosion, contamination, and operational issues caused by water vapor. By ensuring the quality and reliability of compressed air, these systems help extend the lifespan of equipment and reduce maintenance costs.

What factors should businesses consider when selecting a gas generation or air drying system?

When selecting a gas generation or air drying system, businesses should consider factors such as production requirements, capacity, budget constraints, and specific application needs. Consulting with experts in the field can help identify the most suitable solution for their requirements.

Are there any environmental benefits associated with using advanced gas generation and air drying systems?

Yes, advanced gas generation and air drying systems offer environmental advantages, including reduced carbon emissions, energy conservation, and resource efficiency. By producing gasses on-site and eliminating the need for transportation and storage, these systems help minimize environmental impact and promote sustainability.